-

iestinstrument

How to Select the Right Battery Cyclers: 5 Essential Tips

1. Introduction

As a fundamental component of modern energy systems, batteries play a critical role in numerous applications including consumer electronics, electric vehicles, and energy storage systems. A high-performance battery cyclers is essential not only for R&D and quality assurance but also for evaluating performance, safety, and lifecycle management. For research institutes and industrial users, choosing a cycler that truly fits your testing needs is a vital and often challenging decision.

IEST specializes in designing and manufacturing high-precision battery test systems and electrochemical analyzers. We deeply understand the practical demands of users engaged in material research, cell development, module integration, and failure analysis. Our products are built on three core principles: ultra-high precision measurement, system-level stability, and comprehensive safety protection. Based on extensive industry experience and continuous feedback, we refine device architecture and functionality to deliver reliable and efficient testing solutions.

So, how do you systematically evaluate and select the most suitable battery cyclers from the many available options? Below are five practical dimensions to evaluate when choosing any battery cyclers or battery test system.

2. Five Key Factors for selecting a Battery Cycler

Battery cyclers core job is to control and measure voltage and current precisely over a very wide range. Look for:

-

multi-range/automatic current switching (nanoamps → amps)

-

proven linearity and low noise across ranges

-

robust thermal management for long-duration tests

-

traceable calibration and hardware redundancy (overcurrent/overvoltage interlocks)

Why it matters: Poor hardware leads to noisy, biased or unsafe data — especially for low-current material screening or long formation protocols.

IEST’s Strengths:

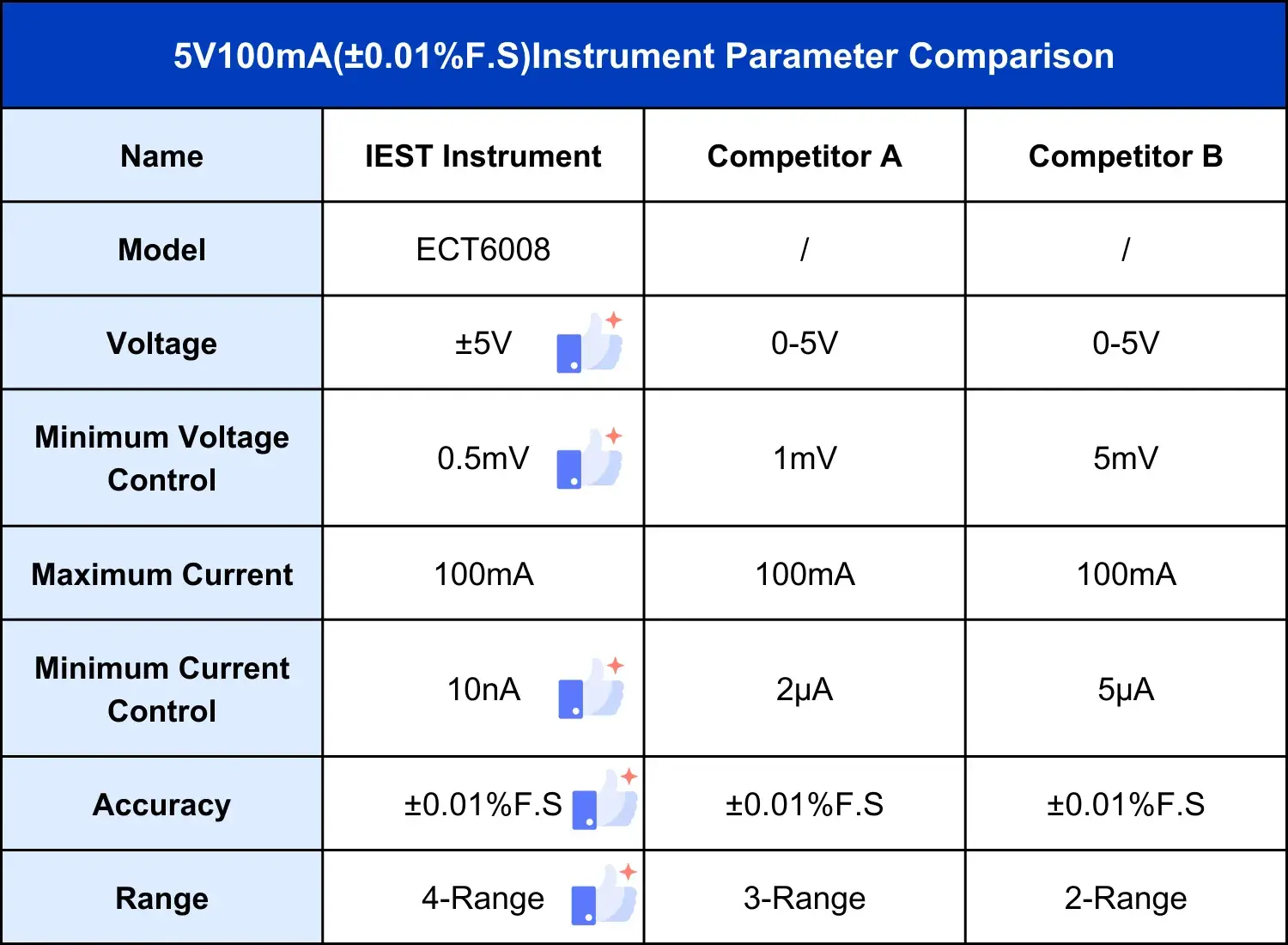

Our ECT Series High-Precision Battery Cyclers and ERT Series Electrochemical Workstations deliver voltage and current accuracy as high as 0.01%, with current ranges spanning from nanoamperes to amperes. The advanced 4-range current design accommodates diverse testing needs. Each unit is calibrated and verified with CNAS-certified reports, guaranteeing traceable and reliable data. Moreover, the systems incorporate triple-layered protection (hardware, software, and firmware) and support one-click test recovery to ensure uninterrupted long-term operation.

Figure 2. IEST ECT6008-5V100mA High-Precision Battery Cyclers System

Table 1. Parameter comparison of IEST battery cyclers and other equipments

2.2 Software & protocol flexibility — make the cycler work for your experiments

Modern battery cyclers are only as useful as their software. Essential features include:

-

native support for CV, EIS, GITT/PITT and complex scriptable sequences

-

multi-step and conditional scripting for automated formation/aging

-

real-time plotting, remote control and API/scripting access for automation

Why it matters: Flexible software lets you automate repetitive formation procedures, integrate EIS pulses, and scale experiments without manual intervention.

IEST’s Strengths:

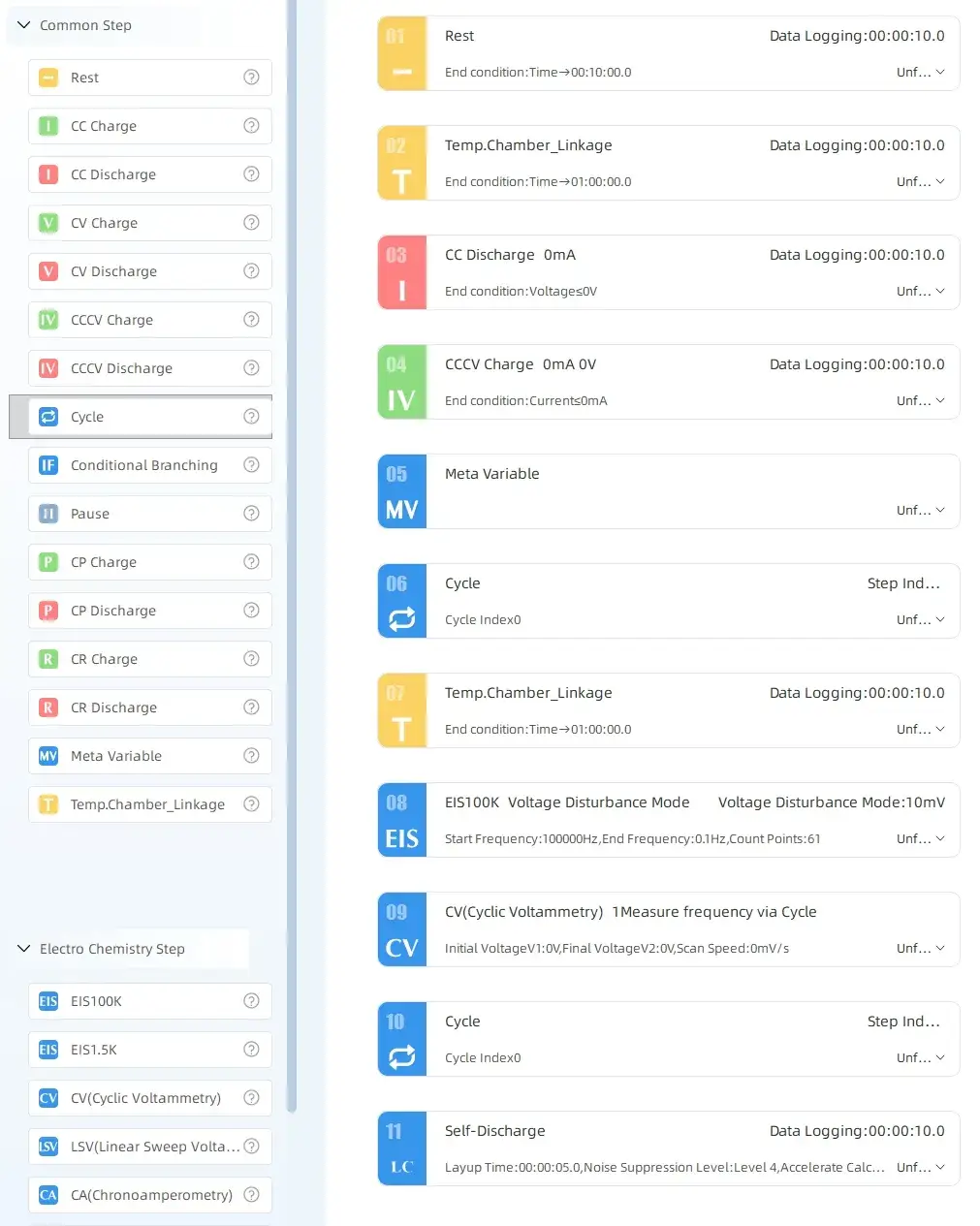

IEST offers self-developed software that supports multi-step sequence setup, real-time data visualization, and script-based control. Whether performing capacity tests, Coulombic efficiency evaluation, in-situ EIS, or cycle-life impedance tracking, all can be executed seamlessly on a single platform, greatly improving R&D efficiency.

2.3 Data handling — high-speed sampling, advanced analysis & export

Important data considerations for battery cyclers:

-

sufficient sampling cadence to capture transients (millisecond–subsecond where needed)

-

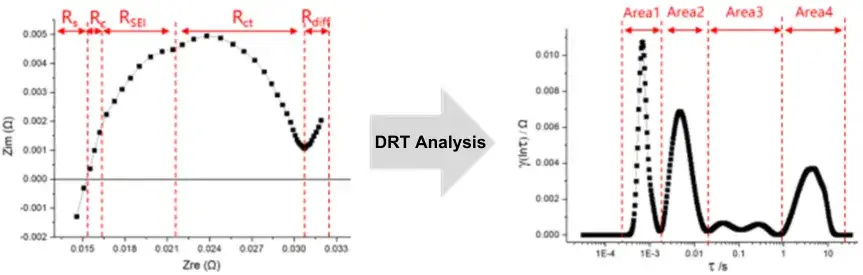

onboard analysis modules (dQ/dV, DRT, EIS fitting) to accelerate insight extraction

-

reliable data backup and convenient export formats (CSV, Excel, etc.)

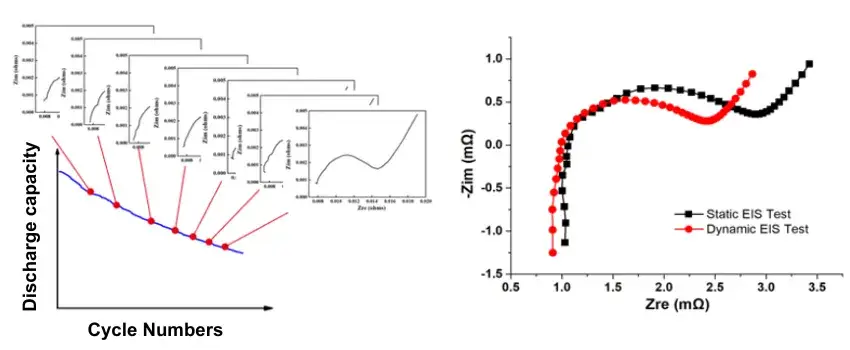

Why it matters: High sampling and built-in analytics help detect subtle behaviors like phase transitions, impedance growth and side reactions that raw logs alone may miss.

IEST’s Strengths:

Our systems support high-speed data sampling (up to 0.01s intervals) and real-time data backup. The integrated analysis toolkit includes modules for CV, EIS, dQ/dV, and more, helping to identify critical behaviors like phase transformation, side reactions, and impedance changes. Data can be easily exported in multiple formats (CSV, Excel, etc.) for reporting or further processing.

Figure 4. IEST Multi-functional Data Analysis Software

Figure 5. Cycling EIS and Dynamic EIS Testing

Figure 6. DRT Analysis of IEST EIS Curves

2.4 Expandability & multi-parameter coupling — integrate cyclers into broader test setups

A good battery cycler should fit into a broader test ecosystem:

-

auxiliary channels for T/P/thickness/force sensors

-

Ethernet/RS485/API interfaces for environmental chambers, gloveboxes or pressure rigs

-

modular channel expansion (add channels without replacing the whole system)

Why it matters: Real-world testing increasingly needs synchronized multi-physics data (temperature, pressure, thickness) to explain electrochemical phenomena.

IEST’s Strengths:

We provide the Aux_Module series—high-precision accessories for measuring temperature (via T-type thermocouples or PT100), voltage, pressure, and more. We also offer customized integration solutions with environmental chambers. Communication between the mainframe and modules is based on Ethernet, ensuring stable and flexible system configuration for a wide range of testing scenarios.

Figure 7. IEST High-Precision Auxiliary Module: Temperature, Voltage, Pressure

2.5 Safety features & application support — protection + vendor services

Safety and supplier services are non-negotiable for high-energy battery work:

-

built-in protections (OV/OC/OT/short) with automatic shutdown and logging

-

remote monitoring and alarm systems

-

responsive technical support, training and application consulting

Why it matters: Fast vendor support and rigorous safety features reduce downtime, prevent accidents and improve test reliability.

IEST’s Strengths:

We implement multi-tier safety strategies and provide remote monitoring and alarm functions. With a strong customer service network and rapid response mechanism, we offer end-to-end support including application consulting, system training, and data analysis. We have rich experience in advanced applications such as impedance modeling, lifetime prediction, and consistency screening.

3. Match the Battery Cyclers to Your Use Case

-

Materials R&D / screening: Prioritize low-current precision, high sampling and EIS capability.

-

Cell engineering & formation: Choose stable multi-channel cyclers with scripting, thermal control and automated formation recipes.

-

Production QA & sorting: Opt for throughput, repeatable templates and automated reporting.

-

Safety / abuse testing: Ensure compatibility with fixtures for nail/overcharge/thermal tests and robust logging.

4. Common Buying Pitfalls (avoid these)

- Ignoring scalability: Choose modular cyclers and open APIs to avoid costly platform replacements.

- Underestimating after-sales: Vendor training and fast service are crucial for long-term uptime.

- Chasing low upfront price: Low-cost units often compromise on precision, stability and safety — increasing total cost of ownership.

5. Quick Cycler Procurement Checklist

-

Does the unit maintain precision across your full voltage/current range?

-

Is sampling cadence adequate for your transient tests?

-

Are CV, EIS, GITT/PITT and scripting supported natively?

-

Can you integrate temperature/pressure/thickness sensors?

-

Is the device traceably calibrated and documented?

-

Does the vendor offer fast support and training?

-

Are exported formats compatible with your LIMS or analysis pipeline?

6. Conclusion

Selecting the right battery cyclers requires careful evaluation of your testing requirements, performance parameters, and supplier support. It is ultimately about choosing a dependable technology partner. IEST is committed to providing high-precision, safe, and intelligent testing solutions under the principle of “Accurate Measurement, Trusted Operation, and Smart Analysis.” Take your time to make an informed choice—contact us today for a personalized battery cyclers solution.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.