-

iestinstrument

How to Accurately Measure the Direct Current Internal Resistance(DCIR) of Batteries

1. What is DCIR?

Direct Current Internal Resistance (DCIR) refers to the resistance value calculated in accordance with Ohm’s Law by applying a DC current step signal to a battery and measuring the resulting change in its voltage. DCIR represents the total internal impedance of the battery, which includes ohmic resistance and polarization resistance. As a core component of new energy vehicles, energy storage systems, and consumer electronics, the performance and safety of batteries have always been the focus of the industry. DCIR is one of the most commonly used and intuitive performance parameters in battery testing. It is not only closely related to the power characteristics and energy efficiency of the battery but also provides important references for life prediction and safety assessment.

2. Why is DCIR Testing So Important?

2.1 Directly Reflects the Battery’s State of Health (SOH)

- Internal Resistance and Aging: During the use and aging of a battery, its internal chemical materials and physical structure will gradually degrade (such as loss of active materials, electrolyte decomposition, thickening of the Solid Electrolyte Interphase (SEI) film, etc.). This degradation directly leads to an increase in the battery’s internal resistance.

- Quantifying Attenuation: DCIR provides a quantifiable indicator to measure this attenuation. By measuring regularly and comparing with the initial internal resistance value of the battery when it leaves the factory, the state of health and remaining life of the battery can be accurately evaluated. The greater the increase in internal resistance, the more severe the battery capacity attenuation usually is.

2.2 A Key Indicator for Evaluating Power Performance

- Power = Voltage × Current: The output power of a battery depends on its terminal voltage and the current it can supply.

- Impact of Internal Resistance: According to the formula Terminal Voltage = Open-Circuit Voltage – Current × Internal Resistance, when a large current (e.g., during acceleration or startup) passes through, the internal resistance will cause a voltage drop inside the battery. The larger the internal resistance, the greater this voltage drop, resulting in a decrease in the actual operating voltage of the battery.

- Direct Impact: A decrease in operating voltage means a drop in output power. For electric vehicles, this manifests as weak acceleration and difficulty in climbing hills; for starter batteries, it may fail to start the engine; for drones, it may fail to provide sufficient lift.

2.3 An Important Line of Defense for Ensuring Safety

- Risk of Thermal Runaway: According to Joule’s Law (Q=I²Rt), heat is generated when current flows through internal resistance. Batteries with larger internal resistance generate more heat at the same current.

- Overheating Warning: Abnormally high internal resistance may indicate defects inside the battery, such as micro-shorts, poor connections, or local dry-out. These defect points will become local hotspots when operating at high currents, greatly increasing the risk of thermal runaway (fire, explosion). Therefore, DCIR testing can be used as an effective means for battery safety screening to promptly identify “problematic cells”.

2.4 A Core Parameter of Battery Management System (BMS) Algorithms

- SOC Estimation: The BMS needs to estimate the remaining charge (State of Charge, SOC) based on current and voltage. Without accurately knowing the internal resistance, it is impossible to accurately calculate the voltage change caused by the current, leading to significant deviations in SOC estimation.

- Power Prediction: The BMS needs to calculate in real-time the maximum charging and discharging currents that the battery can withstand (e.g., the recoverable energy and output energy bars displayed on the instrument panel). This calculation heavily relies on the real-time internal resistance value. Inaccurate internal resistance data will cause the BMS to be too conservative (limiting performance) or too aggressive (posing dangers).

- Balancing Management: A battery pack is composed of multiple cells connected in series, and the consistency of internal resistance is crucial. Cells with inconsistent internal resistance will generate different amounts of heat and voltage during charging and discharging, exacerbating the imbalance of the battery pack. DCIR testing can screen out cells with abnormal internal resistance to ensure the consistency of the assembled pack.

2.5 A Benchmark for Production Efficiency and Quality Control

- Detection of Process Defects: It can quickly detect manufacturing process defects such as poor tab welding, uneven coating, and insufficient electrolyte wetting. All these defects will directly manifest as abnormal internal resistance.

- Consistency Screening: Sorting cells with consistent internal resistance together is a key step in forming a high-performance and long-life battery pack. A battery pack with poor internal resistance consistency will experience rapid degradation of its overall performance.

3. Basic Principle of DCIR Measurement

- Apply a constant current pulse to the battery.

- Record the instantaneous change in battery voltage.

- Calculate the internal resistance using the formula:

Where: ΔV is the voltage difference before and after the current pulse; ΔI is the magnitude of the pulse current.

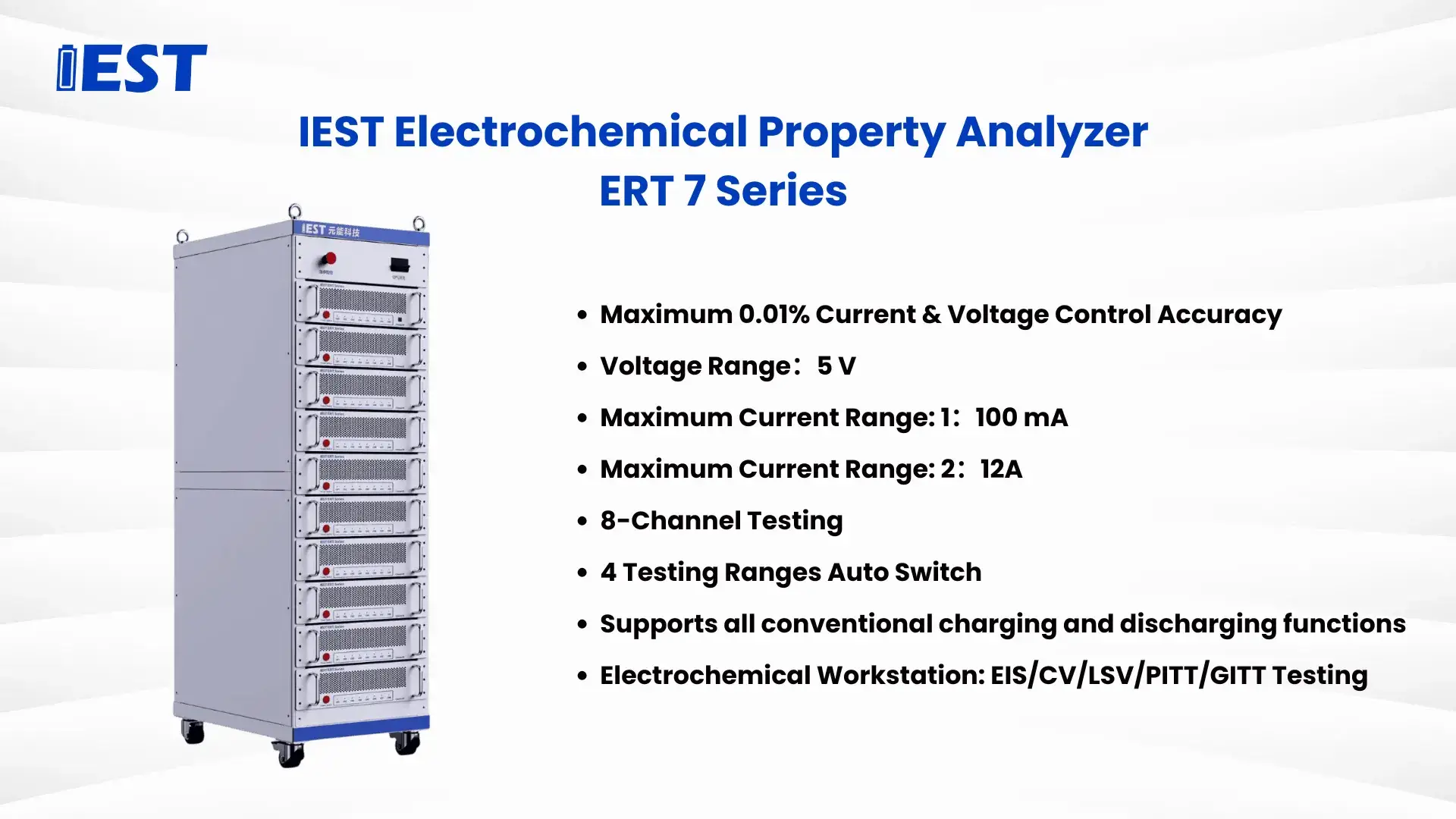

The key point is that a high-precision, high-speed sampling system is essential to capture millisecond-level voltage transients. Yuaneng’s high-precision charge and discharge equipment achieves 0.01% accuracy in voltage and current testing and features a 100Hz high-speed sampling capability. This not only enables precise control of pulse signals but also ensures efficient and reliable collection of critical data.

4. Test Step Settings

4.1 Standstill Phase

- Purpose: To ensure the battery reaches a stable Open-Circuit Voltage (OCV) state.

- Function: To eliminate electrochemical disturbances caused by previous operations.

4.2 Constant Current Discharge Pulse (0.2C-rate, 10s)

- Apply a constant current pulse to the battery for 10 seconds.

- Record the process of instantaneous voltage drop and gradual stabilization.

- This is the core data source for calculating DCIR.

4.3 Short Pulse Verification (0.2C-rate, 1s)

- Conduct another voltage change test under a shorter pulse.

- Used to analyze the dynamic response and polarization effect of the battery.

- Helps to obtain a more refined internal resistance model.

5. Advantages of Our Testing Instruments

5.1 High-Precision Sampling

- Voltage precision can reach the microvolt level, ensuring the capture of instantaneous voltage changes.

- Stable current control enables more accurate pulse application.

5.2 Flexible Step Design

- Supports C-rate modes (e.g., 0.2C, 0.5C), facilitating the testing of batteries with different capacities.

- Users can quickly configure steps according to IEC standards or custom requirements, and save step templates for subsequent use.

5.3 Powerful Data Processing Capability

- Automatically calculates battery internal resistance, reducing manual analysis errors.

- Supports data export for further modeling and analysis.

5.4 Compliance with International Standards

- Fully compatible with battery testing standards such as IEC 61960.

- Meets various application scenarios such as scientific research, certification, and quality inspection.

5.5 Safety Protection Mechanism

- The equipment is equipped with over-voltage, over-current, and over-temperature protection.

- Ensures the dual safety of the equipment and the battery during the testing process.

6. Application Scenarios

- Power Battery R&D: Analyzing the impact of different positive and negative electrode material systems on internal resistance.

- Production Quality Inspection: Quickly screening cells with abnormal internal resistance to improve consistency.

- Energy Storage System Verification: Monitoring changes in the internal resistance of large-scale energy storage batteries to prevent failures.

- Scientific Research Experiments: Combining methods such as Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) to establish a more comprehensive electrochemical model.

7. Conclusion

- The internal resistance value is equivalent to the patency (resistance) of blood vessels. Low resistance means smooth blood (current) flow and strong blood-pumping capacity of the heart (battery).

- Changes in internal resistance reflect the aging and pathological changes (aging and defects) of the body.

- By measuring this indicator, doctors (engineers) can judge a person’s physical fitness (power performance), health status (SOH), and the risk of stroke or myocardial infarction (safety), and formulate treatment plans (BMS management strategies) accordingly.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.