-

iestinstrument

The Secret Weapon of Electrochemical Research—The Three Electrode System

1. What Is the Three Electrode System?

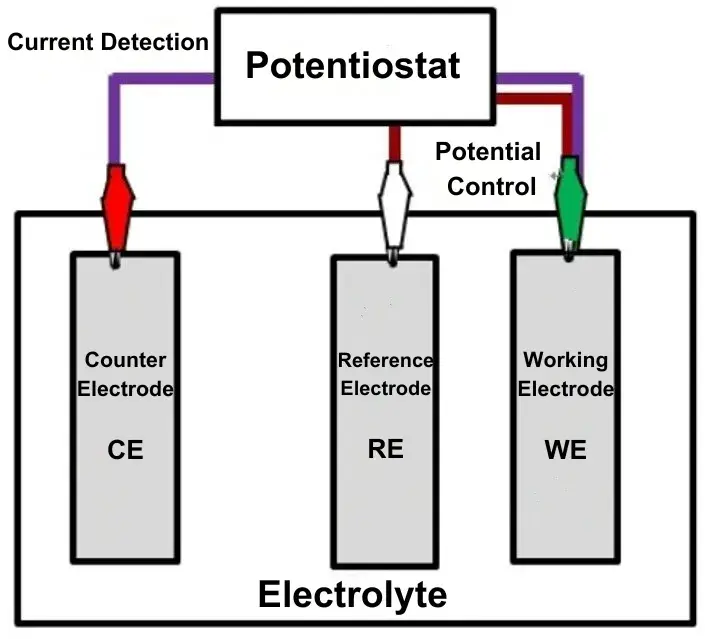

The three electrode system consists of three electrodes: the Working Electrode (WE), the Counter Electrode (CE), and the Reference Electrode (RE). Each electrode has its unique function and role.

-

Working Electrode (WE): This is the heart of the study. In electrochemical experiments, the chemical reactions predominantly occur at the surface of the working electrode—it is like the test field where reaction processes and outcomes are observed and recorded. The working electrode must satisfy several criteria: (1) the studied electrochemical reactions should not be affected by reactions occurring on the electrode itself, and it should operate over a wide potential range; (2) it must be inert to the solvent or electrolyte components; (3) the electrode area should be moderate, with a uniform and smooth surface that can be easily cleaned. Typically, working electrodes are made from inert materials. Common solid electrodes include glassy carbon, platinum, gold, silver, lead, and conductive glasses (such as FTO or ITO), while liquid electrodes often involve mercury. When using solid electrodes, proper pretreatment is crucial to ensure experimental reproducibility.

-

Counter Electrode (CE): Also known as the auxiliary electrode, the counter electrode forms a complete current circuit with the working electrode, allowing current to flow through the electrochemical cell. Its primary function is to balance the current of the working electrode and ensure the overall system current remains stable. Materials chosen for the counter electrode are generally highly conductive and chemically stable, such as platinum or graphite.

-

Reference Electrode (RE): This electrode maintains a stable potential and does not participate in the reaction, providing a constant reference point. Its significance lies in offering an accurate benchmark for the working electrode’s potential, thereby ensuring the precision of electrochemical measurements. Common reference electrodes include the Saturated Calomel Electrode (SCE) and the Silver/Silver Chloride (Ag/AgCl) electrode.

2. Why Is the Three Electrode System So Important?

Early two electrode systems suffered from inherent limitations, including inaccurate potential control due to polarization effects and overlapping contributions from both electrodes. The introduction of the RE in the 1920s revolutionized electrochemical measurements by addressing two key challenges:

2.1 Precise Potential Control:

The introduction of the reference electrode allows the independent measurement and control of the working electrode potential, free from the influence of current. This independence is critical for accurately studying the kinetics and mechanisms of electrochemical reactions.

2.2 Analysis of Complex Electrochemical Systems:

In a two‐electrode system, measurements are often affected by the electrolyte, electrode materials, and current pathways, which compromises accuracy and reproducibility. In contrast, the stable reference provided by the three electrode system enables clearer separation and analysis of the different components and processes within the system.

3. Structure and Connection of the Three Electrode System

Typically, a three electrode system is used in conjunction with an electrochemical workstation or charge–discharge equipment to supply voltage and current while precisely measuring them. It can be understood as having an ammeter connected between the working and counter electrodes and a voltmeter connected between the working and reference electrodes. This arrangement forms two circuits—one for measuring the electrode potential and another for the current—thus the term “three electrode, two‐circuit system.”

Figure 1. Structure of the Three Electrode System

In electrochemical research, especially in battery studies, the three electrode system has become a standard approach due to its ability to provide precise potential control and independent current measurement. However, to fully leverage its advantages, high‐precision electrochemical analyzers are necessary. Below are key reasons and detailed explanations, exemplified by the IEST Electrochemical Property Analyzer.

Figure 2. Appearance of IEST Electrochemical Analyzer

4. Application Cases

4.1 Precise Potential Control

The reference electrode in a three electrode system provides a stable potential reference for accurately controlling and measuring the working electrode potential. High‐precision workstations feature high sensitivity and low noise, maintaining potential stability even at extremely low currents. This is essential for studying subtle electrochemical changes—for example, the narrow potential window required for SEI (Solid Electrolyte Interphase) formation on lithium-ion battery anodes. The IEST Electrochemical Property Analyzer can control and measure potential variations at the microvolt (μV) level.

Figure 3. Voltage control example: Set value: 4.5 V; measured value: 4.5 V ± 100 μV.

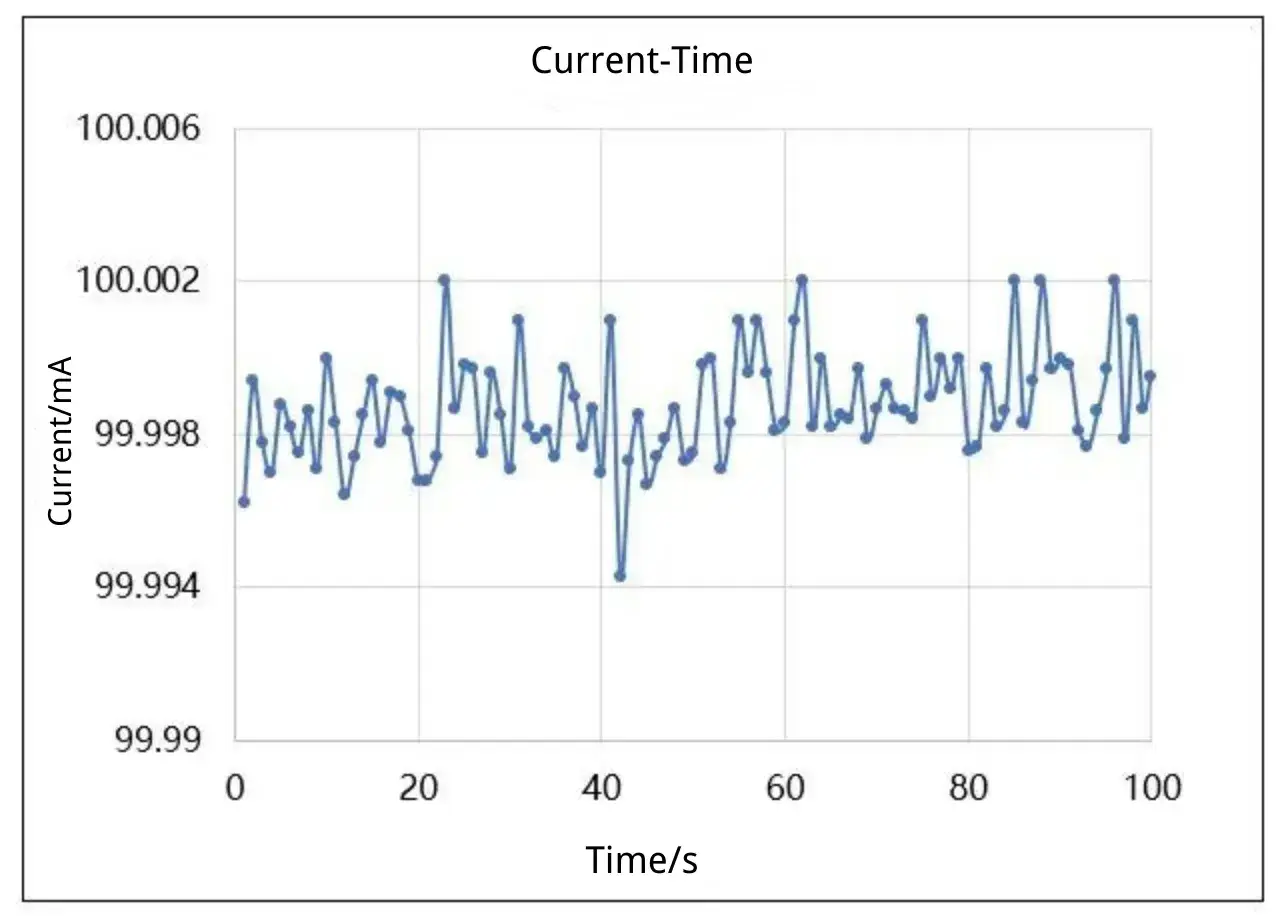

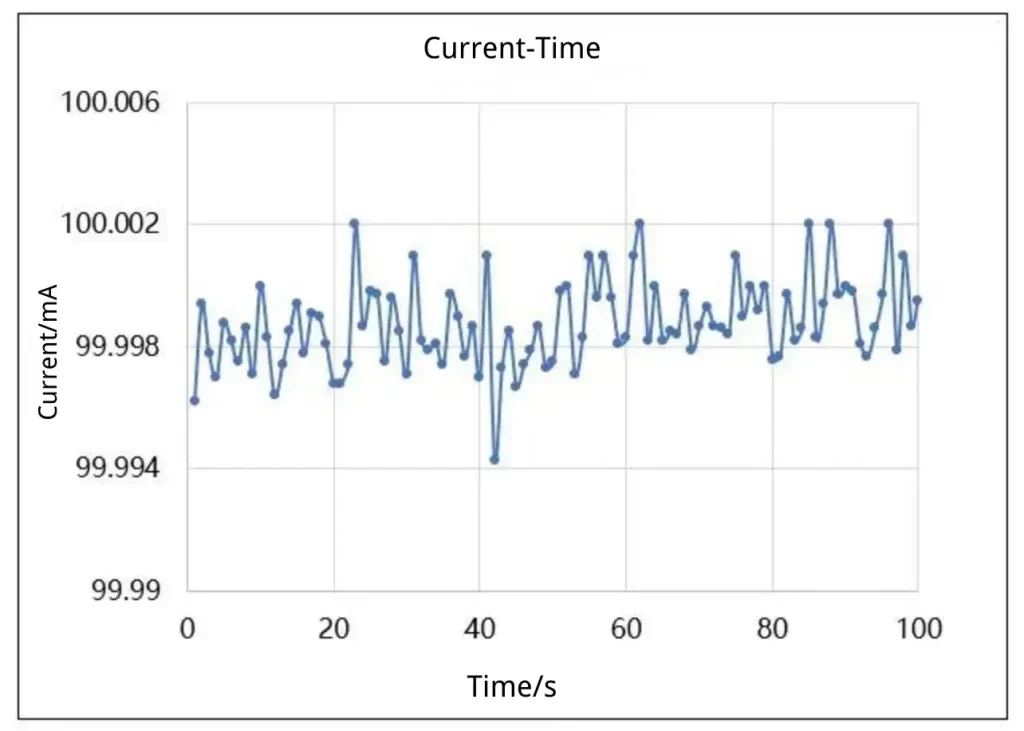

4.2 Accurate Current Measurement

Investigations into the kinetics and mechanisms of electrochemical reactions demand precise current measurements. The IEST Electrochemical Property Analyzer offers current measurement accuracy down to the nanoampere (nA) level, which is crucial for analyzing parameters such as charge transfer resistance and reaction rates in battery materials. For instance, in cyclic voltammetry (CV) tests, accurate measurement of peak currents and potentials is essential. The analyzer enhances current measurement precision to 0.01%, ensuring the accuracy and reproducibility of CV curves.

Figure 4. Current control example: Set value: 100 mA; measured value: 100 mA ± 5 μA.

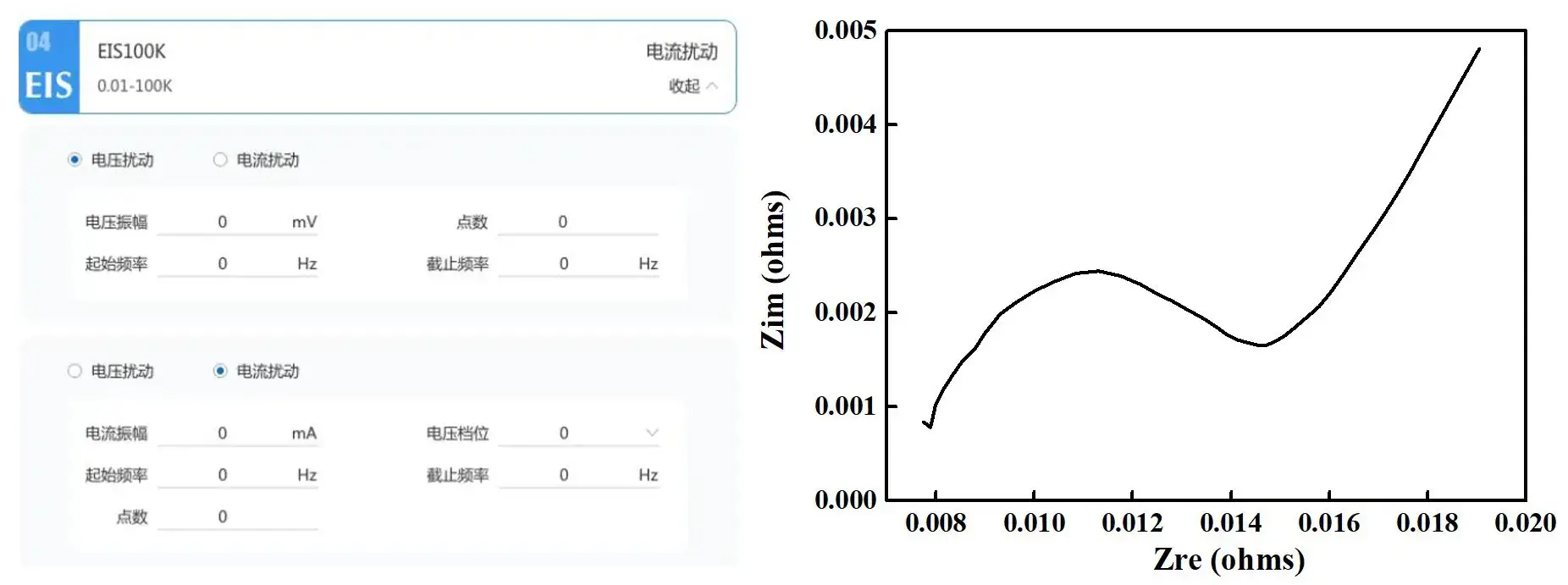

4.3 Low-Noise Characteristics

Electrochemical signals are often weak and susceptible to external noise. The IEST Electrochemical Analyzer incorporates advanced anti-interference technologies to minimize noise and enhance signal purity, which is vital for obtaining high-quality experimental data.

For example, in electrochemical impedance spectroscopy (EIS) tests, high-frequency noise can distort impedance measurements in the high-frequency region. IEST Electrochemical Analyzer integrated EIS module, featuring low-noise design, enables accurate EIS spectra acquisition, aiding in the analysis of battery internal resistance and interfacial properties.

Figure 5. EIS step configuration and data visualization in the IEST Electrochemical Analyzer

4.4 Wide Frequency Response Range

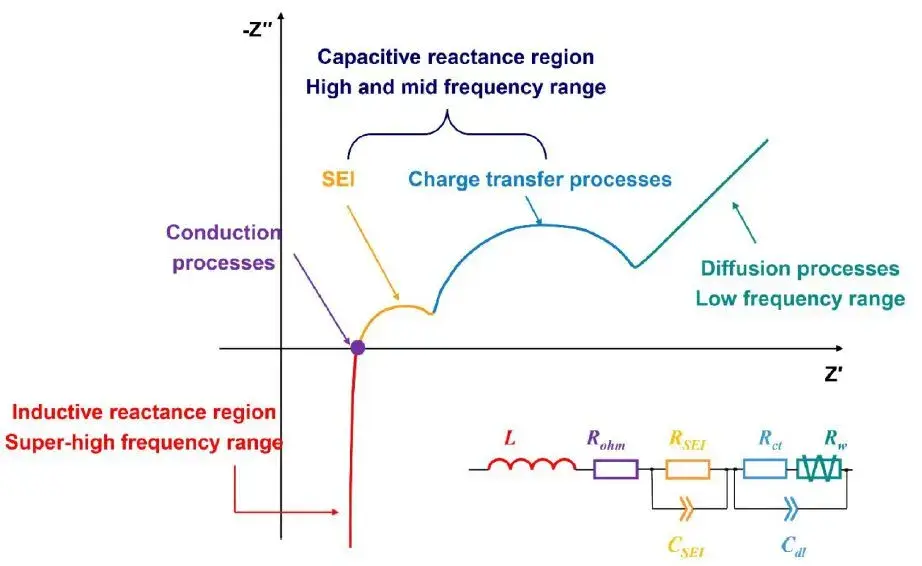

EIS tests cover a broad frequency range—from low to high frequencies. The IEST Electrochemical Analyzer supports frequencies from 0.01 Hz to 100 kHz, accommodating diverse research requirements. Low-frequency data is essential for studying ion diffusion processes, while high-frequency data is critical for investigating charge transfer reactions in electrode materials. The analyzer provides consistent and accurate measurements across the entire frequency range.

Figure 6. EIS characterization of physicochemical properties in electrochemical systems across different frequency ranges

4.5 Multifunctional Integration

The IEST Electrochemical Property Analyzer integrates multiple electrochemical techniques, including cyclic voltammetry (CV), potentiostatic intermittent titration technique (PITT), and galvanostatic intermittent titration technique (GITT). These combined methods enable comprehensive characterization of thermodynamic and kinetic properties of battery materials. Beyond conventional charge-discharge functions, the analyzer incorporates CV and EIS modules to address multifaceted application scenarios.

4.6 Data Processing and Analysis

The IEST Electrochemical Property Analyzer is equipped with advanced software for real-time processing and multidimensional analysis of complex electrochemical data, facilitating the understanding of battery material behavior and performance optimization. While hardware parameters are not the primary bottleneck in the localization of electrochemical workstations, circuit and component optimizations can improve test outcomes. However, cost-benefit trade-offs limit market acceptance of such enhancements. Consequently, intelligent data analysis software capable of detailed data interpretation is imperative. IEST Electrochemical Property Analyzer aligns with this direction, and we welcome inquiries for further technical details.

5. Conclusion

This article provides an in-depth exploration of three electrode systems. Although three electrode cells are not visible in commercial battery products, they play a pivotal role in early-stage laboratory research. EIS measurements resolve SEI film impedance characteristics, CV analyses reveal redox reaction mechanisms and kinetic parameters, while PITT and GITT determine chemical potentials and diffusion coefficients to optimize material design and battery performance. Overall, the introduction of the three electrode system provides feasibility for precise research of complex electrochemical systems. We look forward to the continued unique advantages of the three electrode system contributing to the development of electrochemical science.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.