IEST Instruments

With the widespread application of lithium-ion batteries in electric vehicles and energy storage systems, the consistency of individual cells within battery packs has become a critical factor influencing overall performance and lifespan. Direct Current Internal Resistance (DCIR), a key parameter for assessing battery health and power characteristics, directly determines the effectiveness of cell sorting and pack optimization through the precision and efficiency of its testing methodology. DCIR reflects the combined resistance of ion migration and electron conduction within lithium-ion batteries, closely correlating with polarization characteristics and aging. In power battery modules, if the DCIR variation among individual cells exceeds 5%, it may lead to uneven current distribution during charge/discharge cycles, accelerating localized aging or even triggering thermal runaway. Traditional DCIR testing is susceptible to environmental temperature fluctuations and testing condition variability, resulting in significant data dispersion. This paper introduces a high-consistency DCIR testing method, integrating advanced equipment and standardized protocols, to provide reliable support for battery R&D and production.

The study utilizes the IEST high-precision Electrochemical Property Analyzer ERT6008 Series (see Figure 1). This system supports simultaneous testing of multiple cells with high-accuracy current and voltage modules, which effectively eliminate the impact of current and voltage fluctuations on DCIR measurements.

Figure 1. IEST high-precision Electrochemical Property Analyzer ERT6008 Series

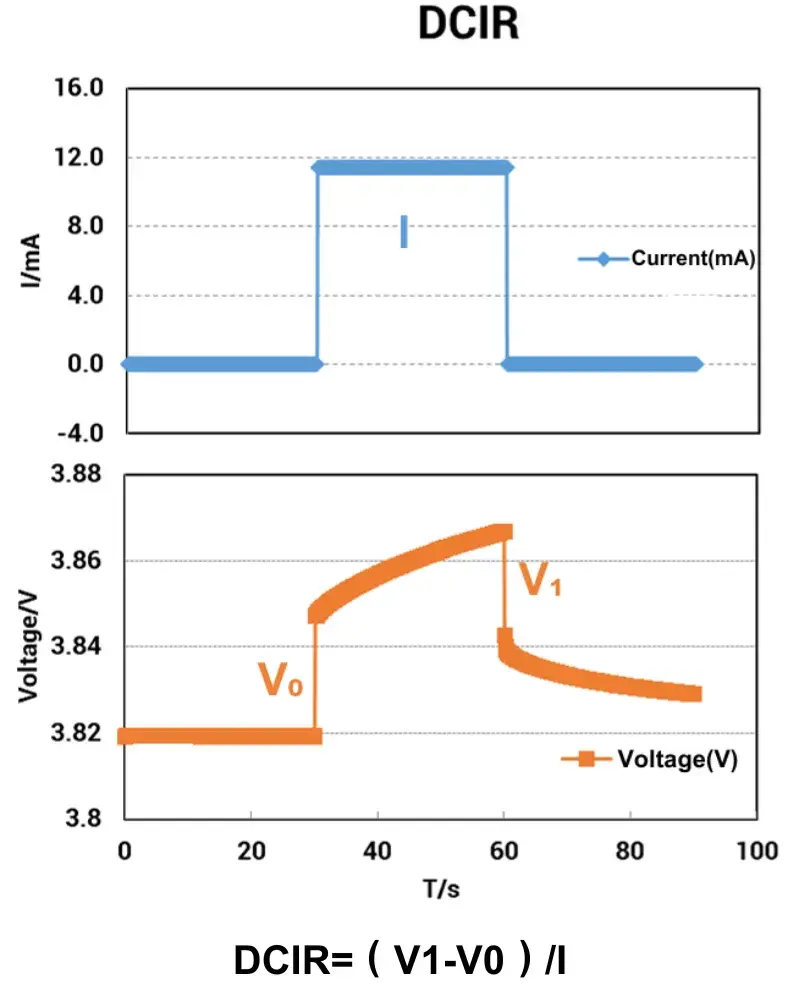

Figure 2. DCIR Testing Current-Voltage Profile

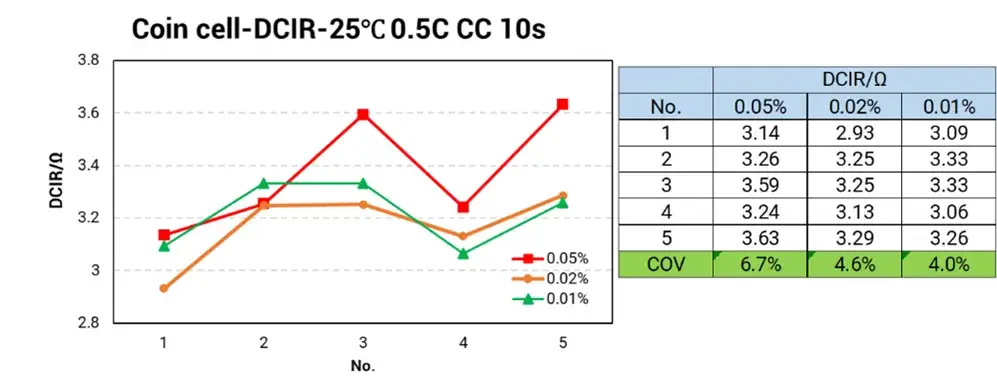

DCIR tests were conducted on 15 parallel half-cells using the three aforementioned voltage-accuracy devices. Results (Figure 3) demonstrate that higher voltage measurement accuracy improves the precision and consistency of voltage change quantification in DCIR calculations, thereby reducing the COV of parallel samples.

Figure 3. DCIR Data Comparison

Based on the IEST ERT series testing equipment, this article establishes a high-consistency DCIR testing method for lithium-ion batteries. By employing high-precision DCIR testing instrumentation, the reproducibility and comparability of the measurement data have been significantly enhanced.

[1] Qin, H., Huo, R., & Wei, D. (2021). Testing and analysis of DC internal resistance in NCM lithium-ion batteries. Battery Industry, (5), 4.

[2] Zhou, J., & Yu, B. (2023). Step charging system and cycle capacity fade mechanism of lithium-ion battery. Power Source Technology, 47(6), 741–744.

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.

Please fill out the form below and we will contact you asap!