IEST Instruments

In new energy vehicles or energy storage stations, lithium-ion batteries are often configured in modular or battery packs, where cells are connected in parallel and series. If any cell has performance defects or safety risks, it may cause the failure of the entire module or battery pack. By performing consistency screening before the battery leaves the factory or is assembled into modules and groups, the effective utilization of the battery can be improved, and the cycle life and safety of new energy vehicles or energy storage stations can be significantly improved. Therefore, it is crucial to ensure the consistency of the cells used in these configurations.

Existing cell grading methods for LIBs rely on parameters such as open-circuit voltage (OCV), capacity, 1000 Hz AC impedance (ACIR), and K-value (self-discharge rate). However, these metrics primarily assess electronic resistance and neglect ionic resistance, which governs internal electrochemical kinetics. Furthermore, consistency evaluation is rarely performed during module/pack assembly, increasing the likelihood of “weak-link” cells that degrade overall system performance.

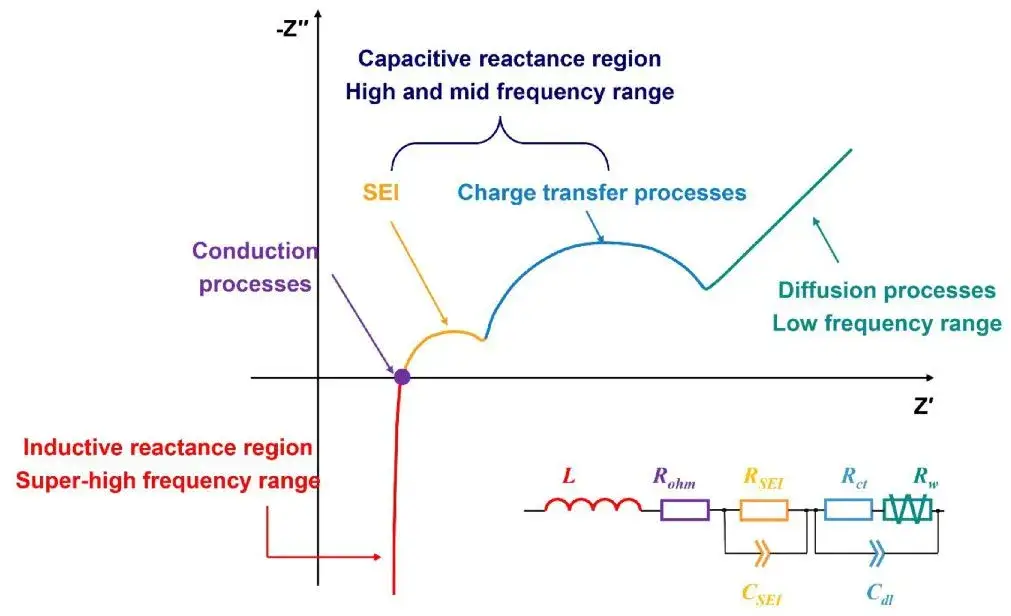

Electrochemical Impedance Spectroscopy (EIS) applies small-amplitude alternating current (AC) or voltage perturbations to a battery and measures its frequency-dependent impedance response. This technique provides insights into electrochemical processes such as double-layer capacitance, charge transfer resistance, and ion diffusion kinetics (Figure 1)【1-3】. A Nyquist plot of LIB impedance typically exhibits distinct semicircles representing processes with different time constants, which can be deconvoluted using equivalent circuit modeling (Figure 1, inset).

Figure 1. Classic Nyquist plot of LIB impedance and equivalent circuit model【2】

EIS enables multi-frequency analysis, capturing both high-frequency electronic conductivity and mid-to-low-frequency ionic processes. Integrating EIS into pre-shipment or pre-assembly screening allows refined consistency classification, reducing the inclusion of outlier cells. Despite extensive academic research (>10,000 publications), industrial adoption of EIS has been limited due to the high cost and complexity of traditional potentiostat-based systems. Additionally, conventional EIS equipment struggles to test high-capacity, low-impedance LIBs without costly current amplifiers.

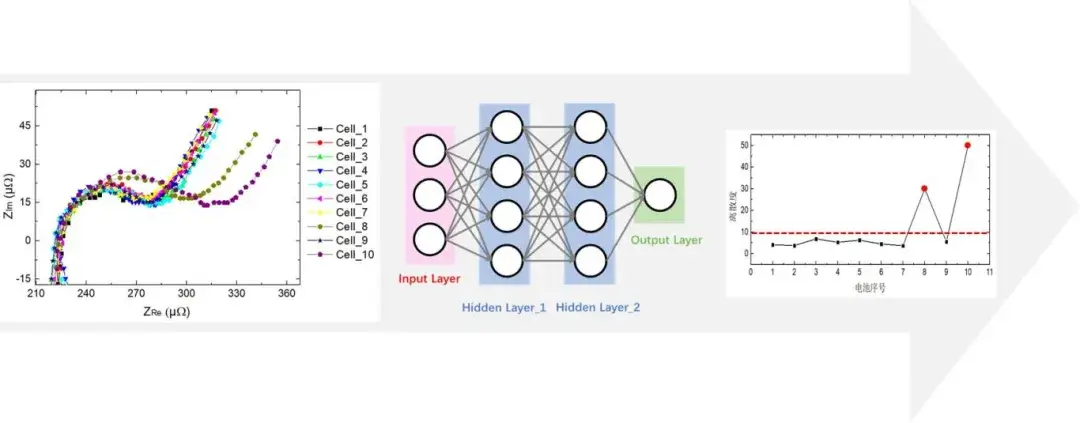

To address these challenges, IEST Instrument has developed an industrial-grade EIS solution—the BIT6000 Battery Impedance Tester (Figure 2a). This system integrates with manual fixtures (Figure 2b) or automated feeding equipment (Figure 2c) to rapidly perform EIS on high-capacity EV/ESS batteries. Advanced neural network algorithms analyze impedance spectra for consistency assessment, enabling precise grouping or rejection of outliers.

Figure 2. (a) BIT6000 Battery impedance tester, (b) manual fixture, and (c) automated feeding system.

Figure 3 compares EIS profiles of ten 340 Ah ESS cells. While high-frequency regions (electronic resistance) appear nearly identical, mid-to-low-frequency data reveal significant discrepancies in charge transfer and ion diffusion for Cells #8 and #10. Neural network-based analysis quantifies cell-to-cell variability, allowing outlier exclusion or gradient-based grouping to ensure module/pack homogeneity.

Figure 3. EIS comparison of 10 ESS cells and neural network-derived discrepancy distribution curves.

EIS-based consistency screening offers a robust solution to the “bucket effect” in LIB systems by evaluating both electronic and ionic resistances. The BIT6000 platform bridges the gap between academic research and industrial application, enabling scalable, high-precision impedance analysis for large-format batteries. By integrating advanced algorithms and automation, this approach enhances battery safety, longevity, and second-life utility, driving progress in sustainable energy storage technologies.

[1] W.X. Hu, Y.F. Peng, Y.M. Wei and Y. Yang, Application of Electrochemical Impedance Spectroscopy to Degradation and Aging Research of Lithium-Ion Batteries. J. Phys. Chem. C 127 (2023) 4465-4495.

[2] T. Osaka, D. Mukoyama and H. Nara, Review-Development of Diagnostic Process for Commercially Available Batteries, Especially Lithium Ion Battery, by Electrochemical Impedance Spectroscopy. J. Electrochem. Soc. 162 (2015) 2529-2537.

[3] A. Battistel and F.L. Mantia, On the Physical Definition of Dynamic Impedance: How to Design an Optimal Strategy for Data Extraction. Electrochim. Acta 304 (2019) 513-520.

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.

Please fill out the form below and we will contact you asap!