Industrial-Grade Battery EIS Tester & Application Solutions

IEST Battery Impedance Tester BIT6000

-

ElS Test for EV Battery & Energy-storage Battery

-

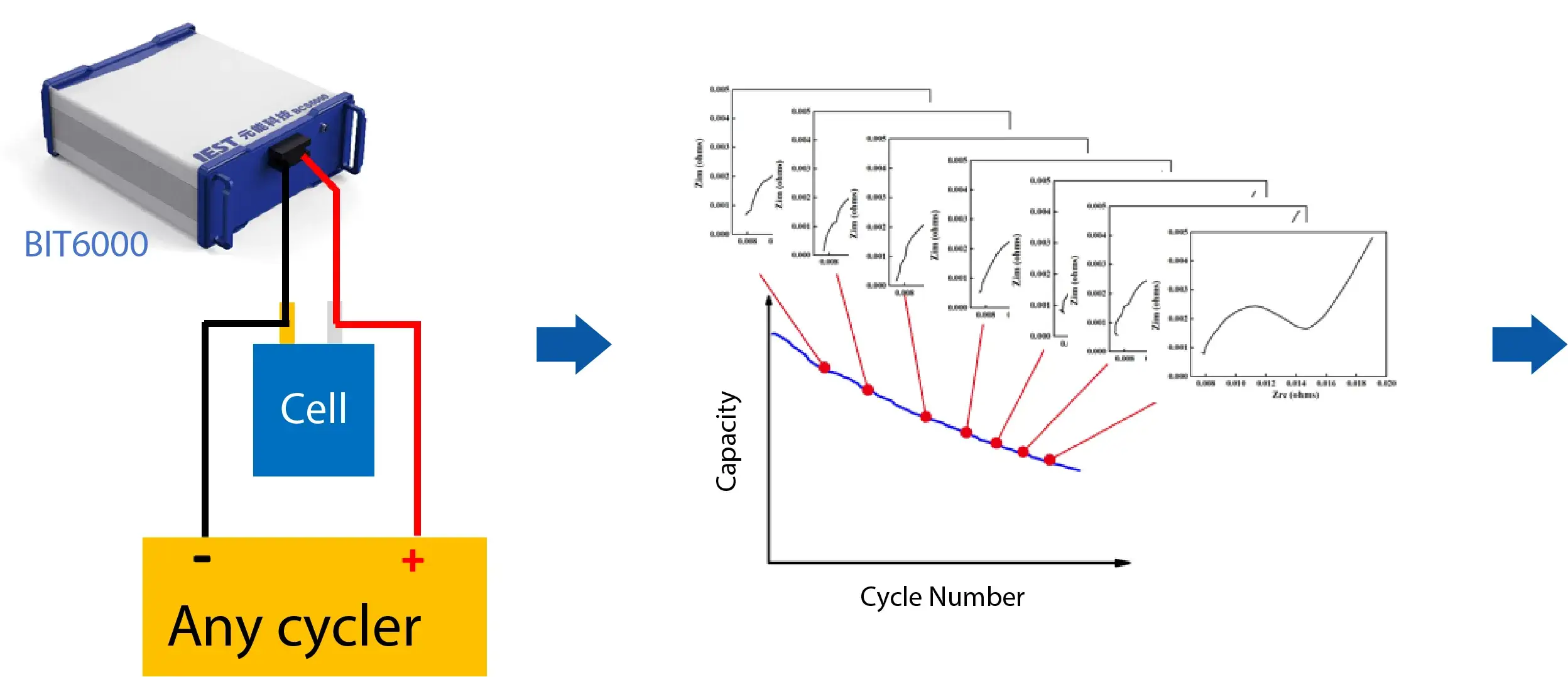

Integration the EIS Test with Battery Cycler

Integration the EIS Test with Battery Cycler -

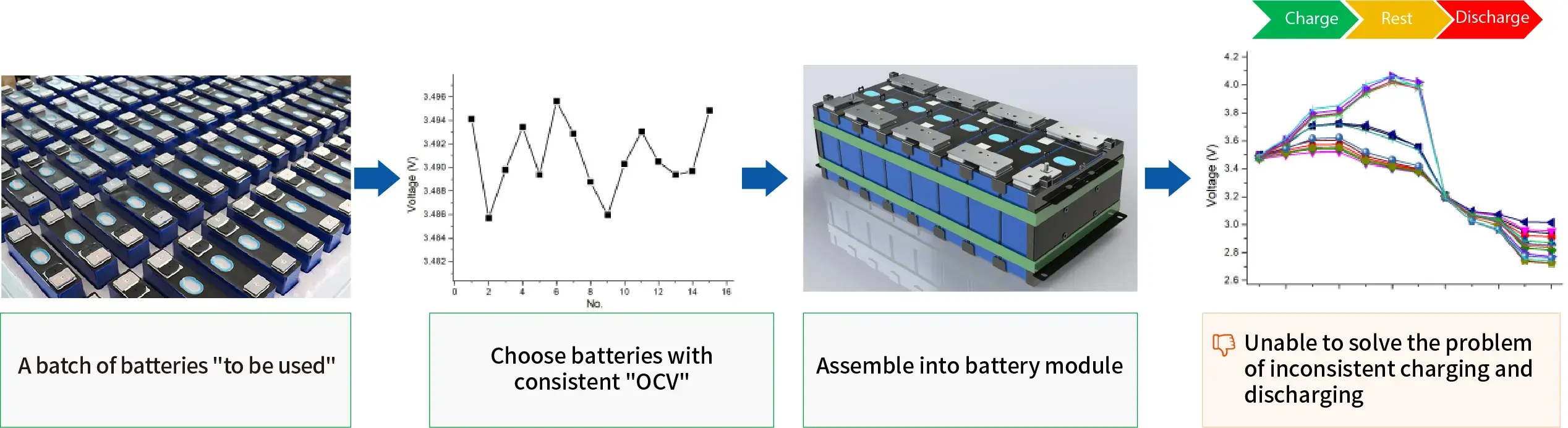

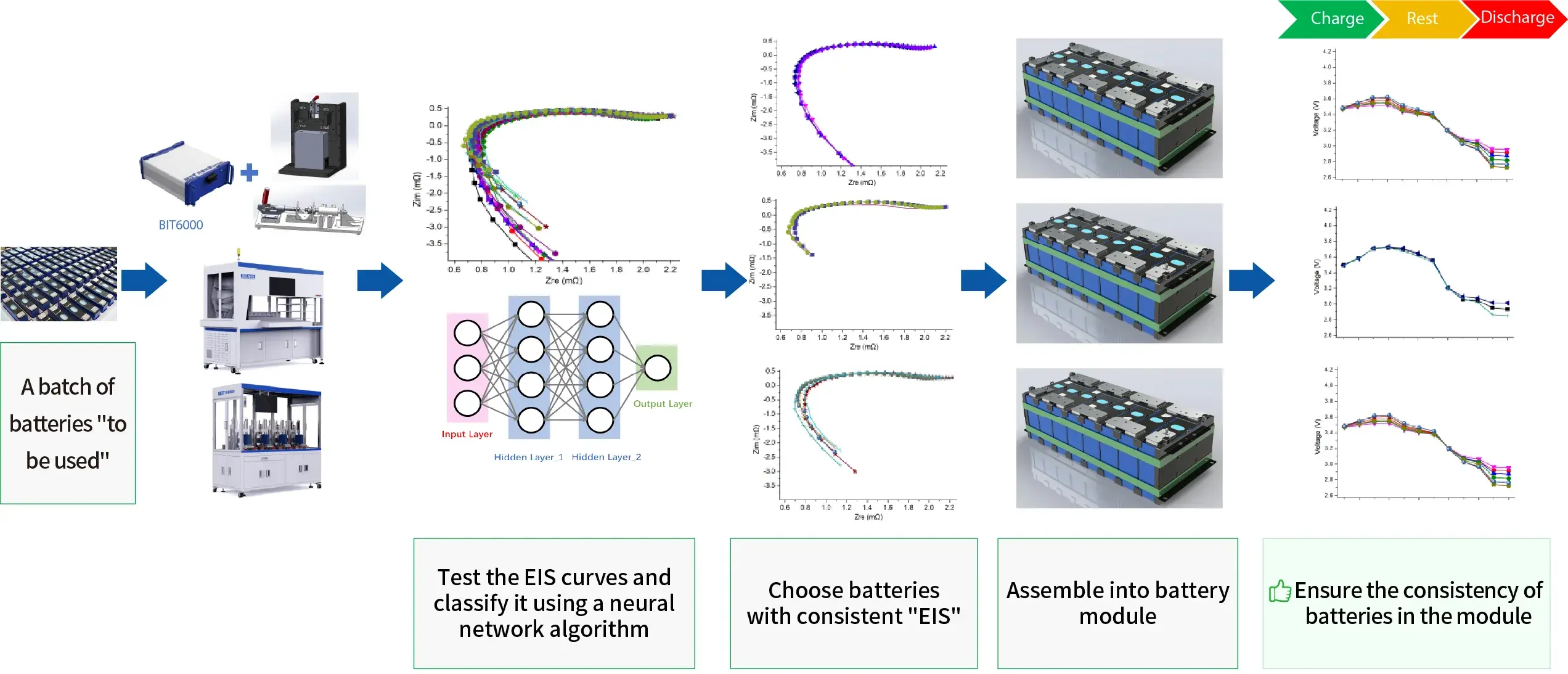

EIS Test Before Module Assembly (Battery Consistency Screening)

EIS Test Before Module Assembly (Battery Consistency Screening) -

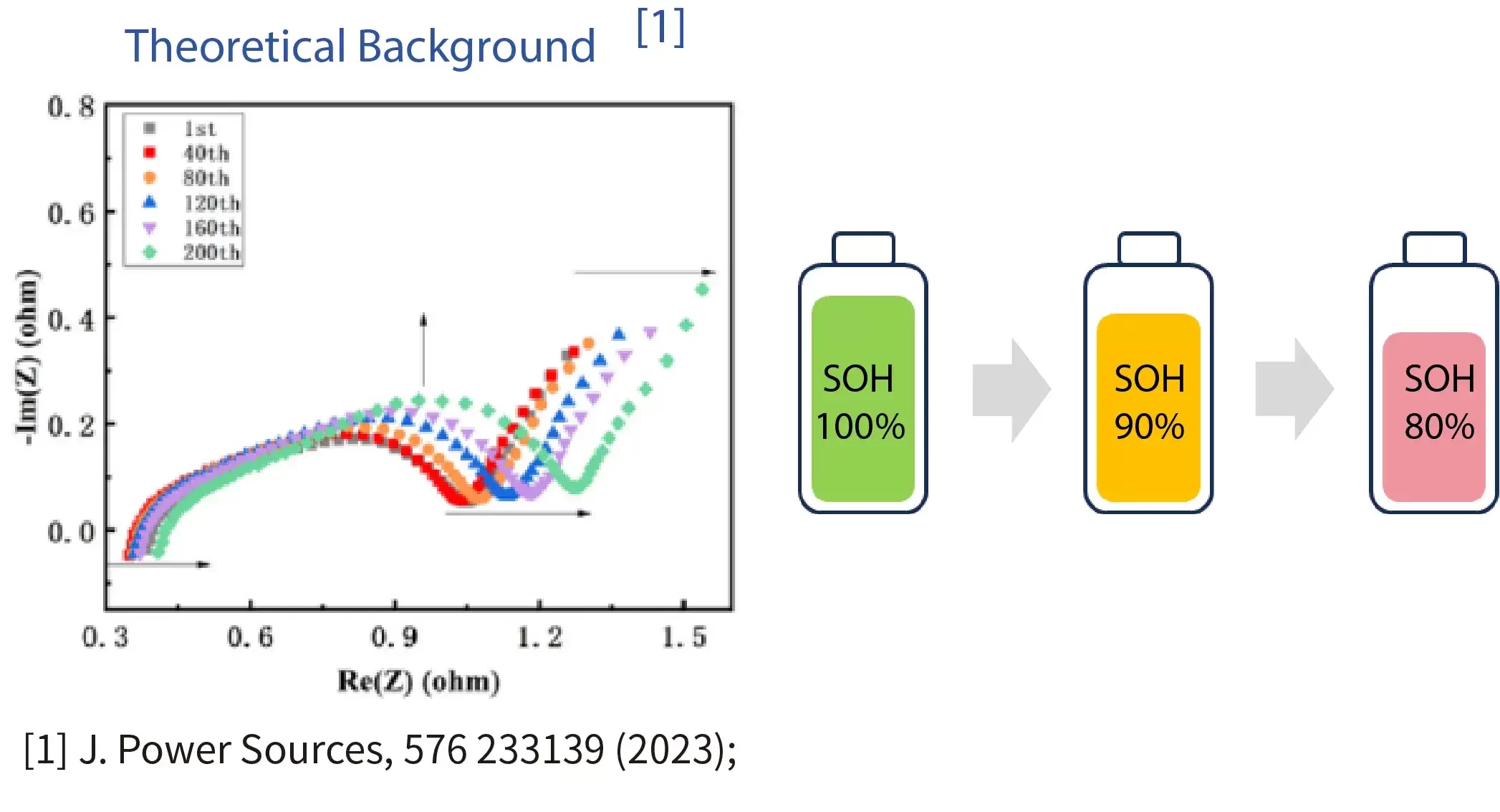

SOH Rapid Estimation(Cascade Utilization)

SOH Rapid Estimation(Cascade Utilization)

Lithium Battery Industry Pain Points

Battery Manufacturers

Q1: The larger the battery capacity, the smaller the internal resistance. Traditional electrochemical workstations cannot perform effective testing and they are expensive if used with current amplifiers.

Q2: Diferent batteries can't be distinguished by OCV or 1000Hz AClR alone. How can the batteries be sorted more finely?

Q3: lf there is an abnormality in the battery, how can we quickly locate the production problem? is it a poor welding? Or a poor formation? Or is it a material failure?

Battery Use & Recycling Companies

Q1: How to judge the battery consistency before assembling the battery module? Relying solely on OCV or 1000Hz ACIR is no longer sufficient.

Q2: Are there diferences between the same type of batteries purchased from different manufacturers? Can they be mixed?

Q3: For recycled or disassembled batteries, what is the remaining SOH (State of Health), and how can they be utilized in echelon applications?

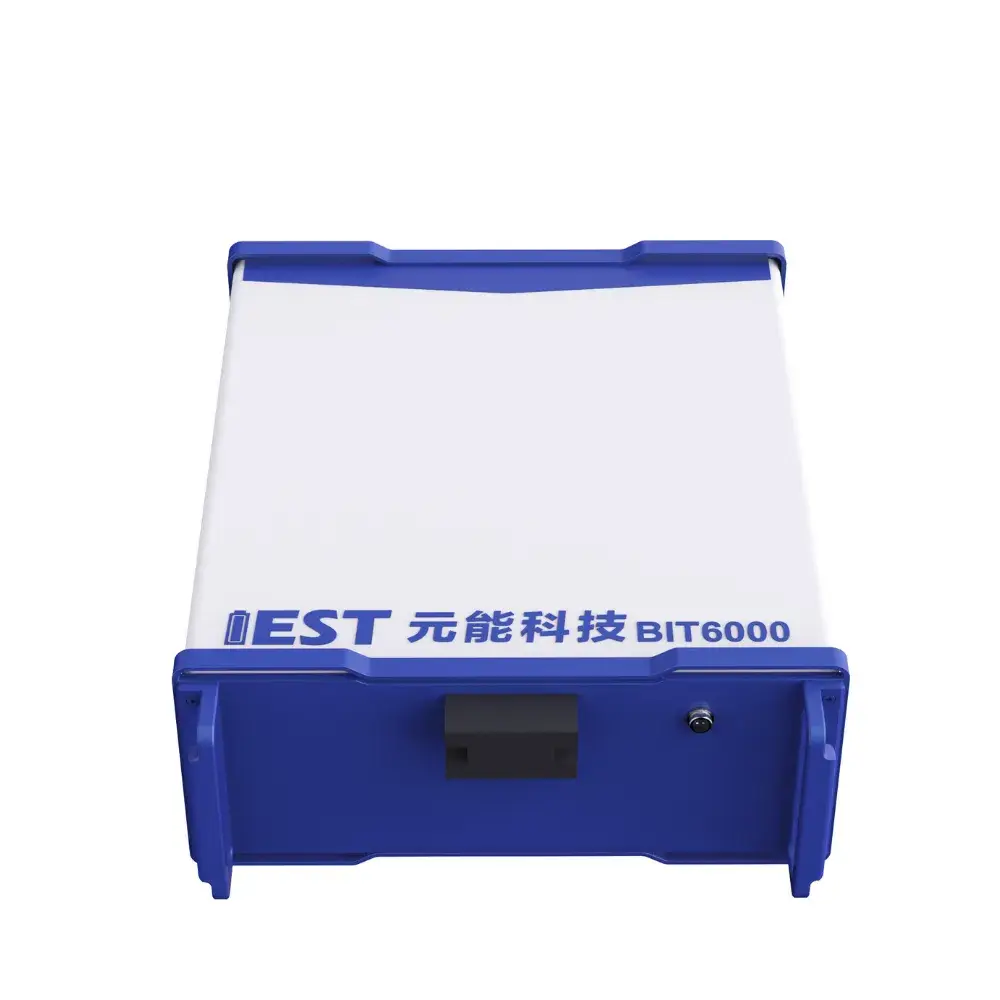

BIT6000 Introduction

Functions & Features:

-

Wide range of applicable cells, ranging from 2Ah to 1000Ah

-

Fast EIS frequency sweep testing, with a frequency rangeof 1500Hz~0.1Hz;

-

Equipped with OCV testing, DCR testing, constant current charge-discharge testing, etc.

-

Battery Consistency Screening.

-

Dynamic fitting screening algorithm for batch screening.

Application Scenario.

Energy Storage Battery

Battery Recycling & Cascade Utilization

Used Car Recycling

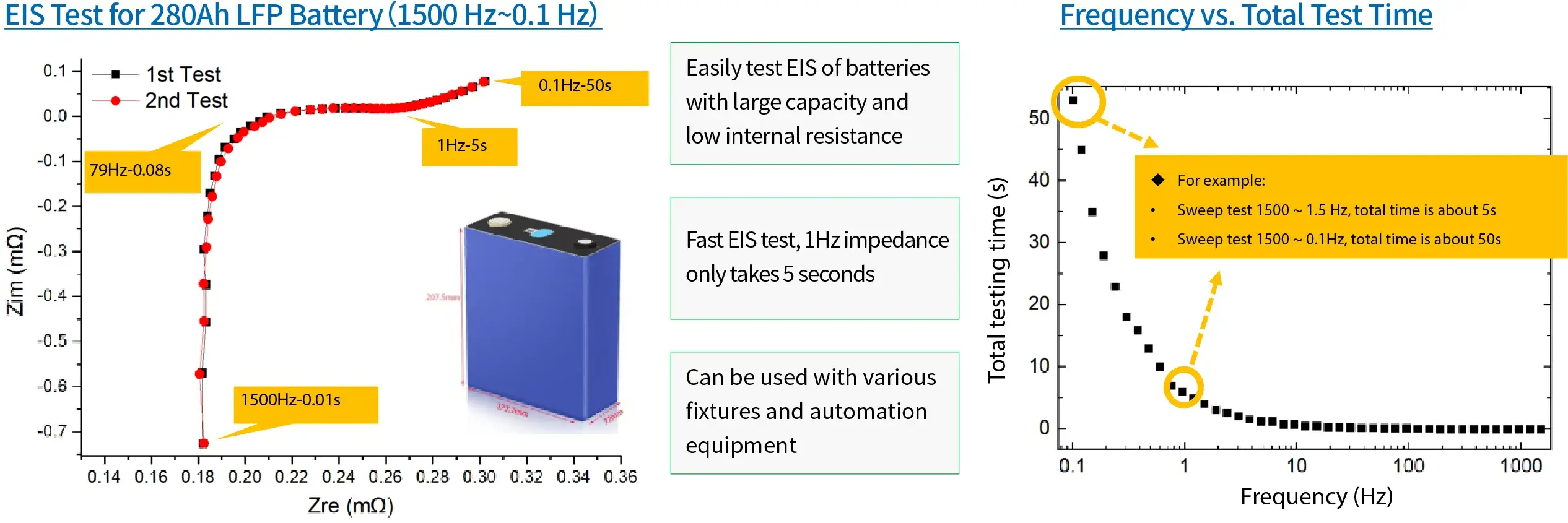

ElS Test of Battery With Large Capacity & Low Internal Resistance.

IEST’s BIT6000 can easily test the EIS of batteries with large capacity (2Ah~1000Ah) and low internal resistance (0.05mΩ~100mΩ). We also support customization various testing fixtures and automation testing equipment.

Note: The EIS test frequency range can be adjusted according to the production line progress and process section

Integration the EIS Test with Cycler.

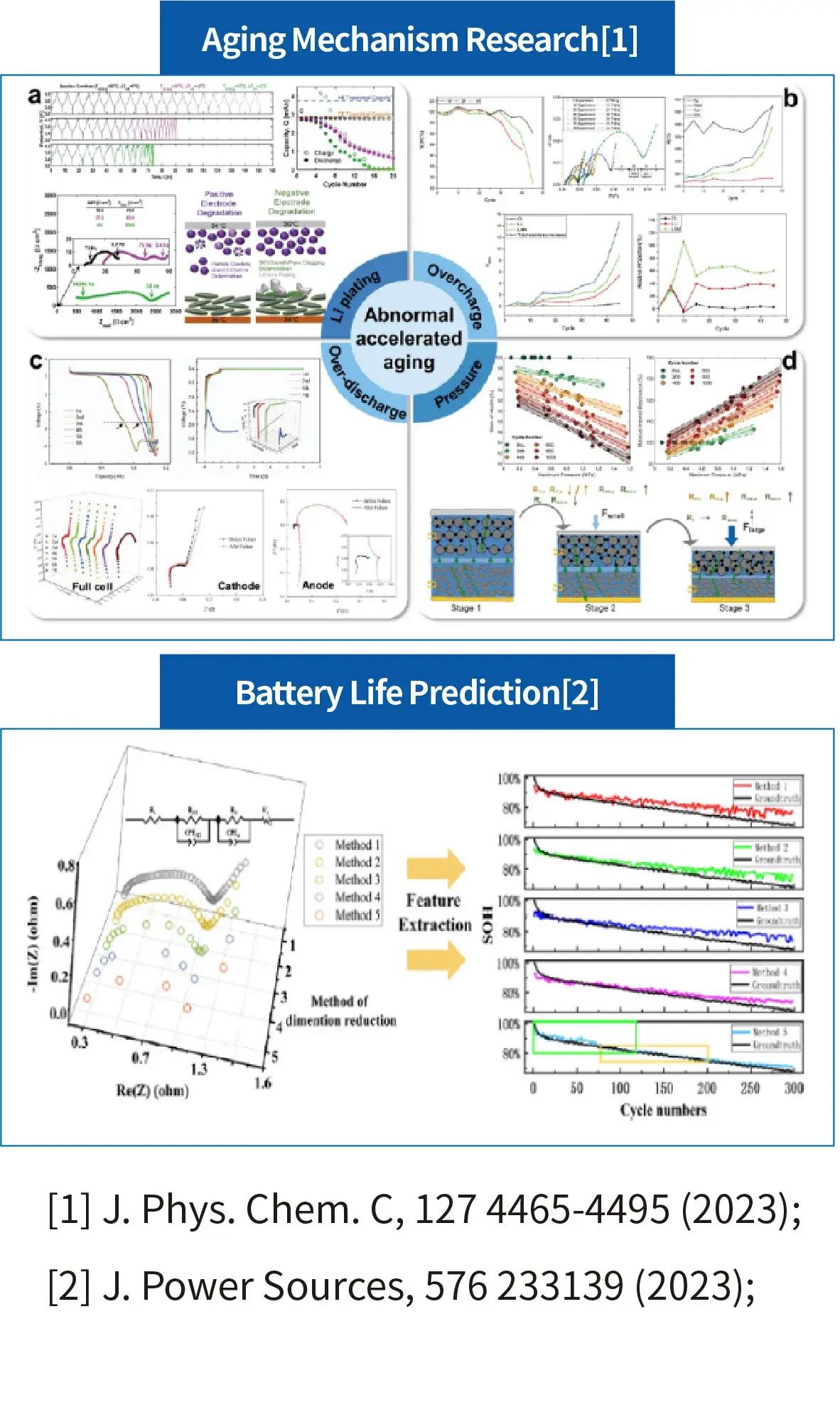

EIS under different SOH & dynamic EIS or operando EIS

Coin cell Cycle EIS Test: 0.01Hz~100kHz, EIS test every 10% SOC

1. IEST BIT6000 can be integrated with any cycler. Users can first use the cycler tester to perform the cyclic aging on the battery, and BIT6000 can automatically perform the EIS testing under different SOH states, which can save the switching time between ”temperature adiustment ⇔ charge and discharge instrument ⇔ electrochemical workstation”

2. IEST BIT6000 can also perform the EIS testing during the charging & discharging process, i.e., dynamic EIS or operando EIS.

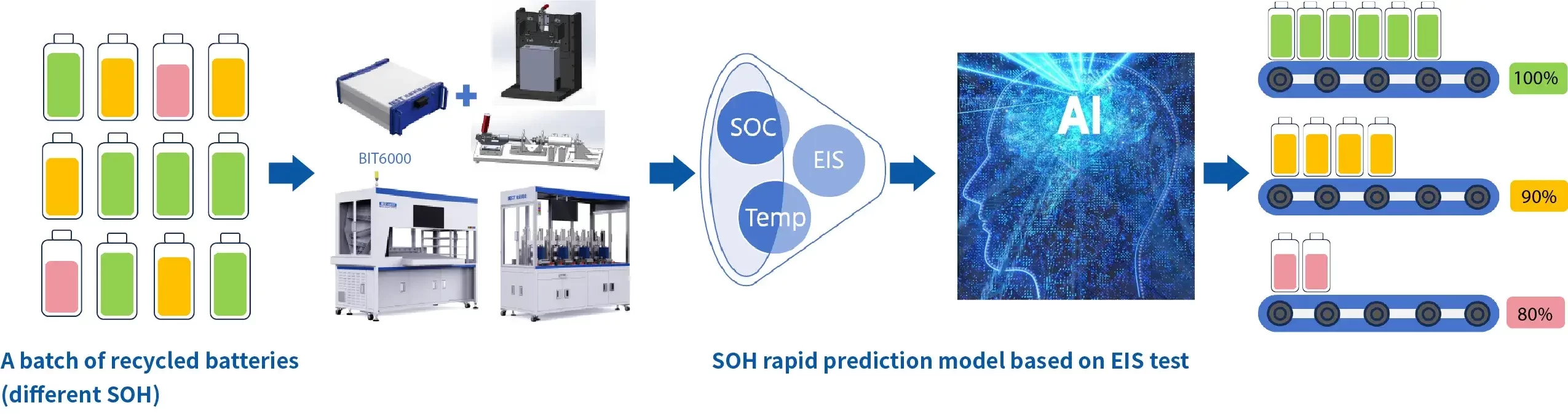

EIS Test Before Module Assembly (Battery Consistency Screening) .

For battery manufacturers producing and assembling modules/packs, EIS testing can be used to check the quality and consistency of battery in the same module/pack.

For EV/energy-storage manufacturers sourcing batteries externally, EIS testing ensures incoming battery quality to maintain the consistency of battery in the same module/pack.

Traditional Battery Sorting Method

lEST's Innovative Battery Sorting Method

SOH Rapid Estimation (Cascade Utilization).

Traditional battery grading and cascade utilization:

- A batch of recycled batteries

- Charge and discharge the batteries

- Grouping and tiered utilization based on capacity

Three Major Disadvantages:

- Long grading time

- High power consumption

- Many channels occupied

IEST’s Rapid Grading Solution:

- A batch of recycled batteries

- Perform ElS test on the batteries

- According to the correlation model between ElS and capacity, conduct rapid capacity division

Major Advantages:

As the battery health (SOH) decreases, its EIS test results will also change accordingly.

- SOH Estimation Accuracy<5% (Big Data Modeling Required)

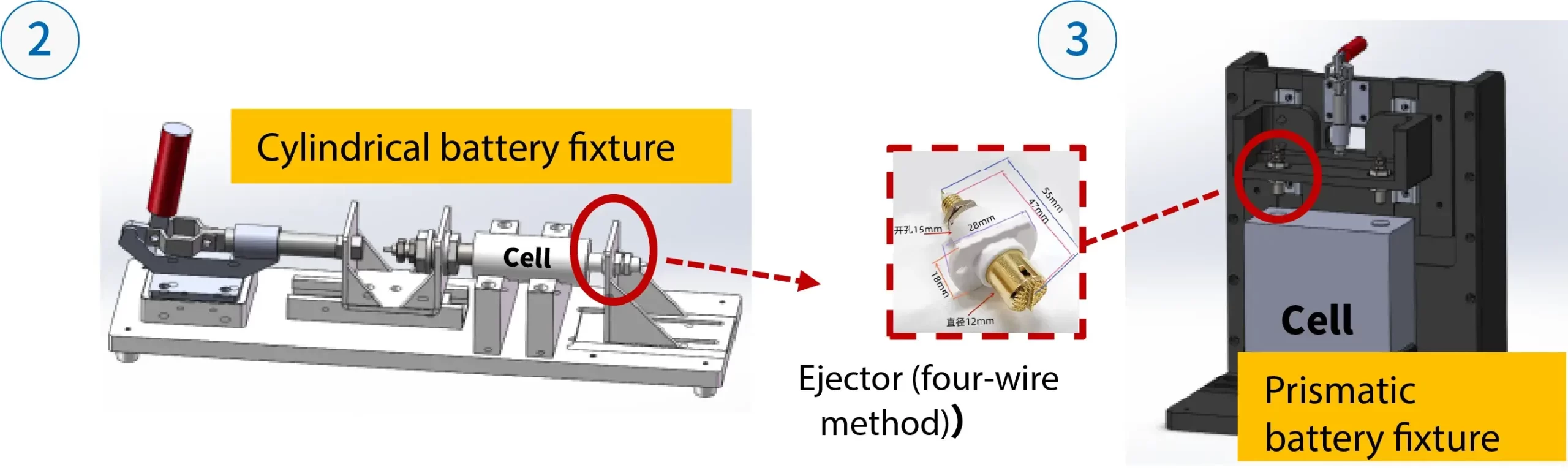

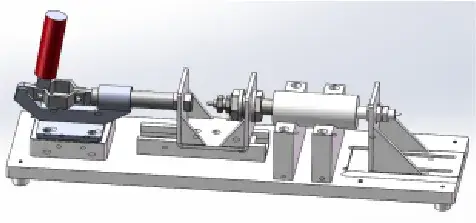

| Battery lmpedance Tester | Adjustable Prismatic Battery Testing Apparatus | Adjustable Cylindrical Battery Testing Apparatus | |

|---|---|---|---|

| Photo |  |  |  |

| Model | BIT6000 | APTB1000 | ACTB1000 |

| Voltage control accuracy | ±0.006% F.S | Applicable to all kinds of prismatic batteries Maximum length *width*height: 284*94*255 mm Maximum tab spacing: 40~240 mm (Other sizes can be customized) | Applicable to cylindrical batteries 18650/21700,etc. Maximum length: 130 mm Diameter range: 18~50mm (Other sizes can be customized) |

| Current control accuracy | ±0.05% F.S | ||

| ElS frequency range | 1500Hz ~ 0.1 Hz | ||

| ElS test range | 0.05mΩ ~ 100mΩ | ||

| Applicable battery capacity | 2Ah~1000Ah Li-ion battery | ||